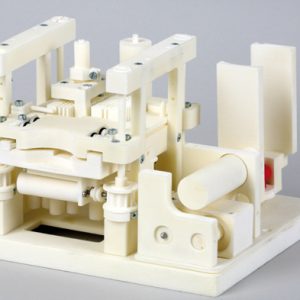

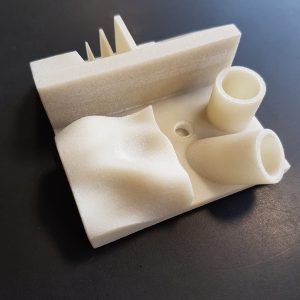

SELECTIVE LASER SINTERING

Selective laser sintering is a generative layer construction process. In this method, the workpiece is built up layer by layer from a powdery starting material with the aid of a laser. The effect of the laser beams can be used to create any three-dimensional geometry with undercuts, e.g. B. Workpieces that can not be produced in conventional mechanical or casting manufacturing.

Characteristics

- Manufacturing highly complex structures

- Models to optimize the functional principle

- Resilient models to check the construction

- Fast and inexpensive production

- no restrictions on the design of the product idea

- Surface finishing possible

Material

PA 650 (Polyamide)

– Dimensional accuracy up to 1/10 millimeter

– High thermal and chemical resistance

– Improvement of the technical properties possible through infiltration

– Dimensions of the installation space 320 x 280 x 400 mm

PA620-MF (fiber reinforced polyamide)

– High specific rigidity and heat resistance

– Anisotropic mechanical properties, the same fiber-filled injection molding materials

– HF-permeable and non-conductive

– Simple surface processing

– Excellent resilience under high temperatures

– Attractive surface finish

DuraFormTM Flex (rubber-like properties)

– Rubber-like flexibility and functionality

– Durable and tearproof

– Durable (resists harsh environmental conditions)

– For tight closures, even under pressure

– Numerous color options available

– High thermal and chemical resistance

– Surface finish possible

– High detail reproduction

– Adjustable shore hardness from approx. 20 to 80 shore A

– Improvement of the technical properties possible through infiltration

– Maximum dimensions 320 x 280 x 300 mm

TPU92 (rubber-like properties)

– Flexible, rubber-like material

– High abrasion and tear resistance

– Extremely resilient

– Shore hardness of A 92

– High detail reproduction

– Surface finish possible

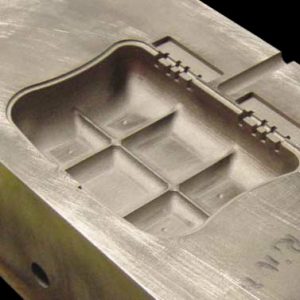

LaserForm A6 (steel-like properties)

– Properties of steel (St. 70)

– Dimensional accuracy up to 1/10 millimeter

– Reworking is reduced to a minimum

– Complex properties such as overhangs, cooling channels and panels can be integrated directly

– High thermal conductivity enables fast cycle times

– No additional costs for casting, machining and NC programming

– Maximum dimensions 320 x 280 x 150 mm

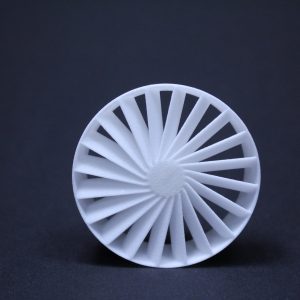

POLYJET 3D-PRINTING

Das Polyjet 3D-Druckverfahren oder auch Multijet Modelling ist ein 3D-Druck Verfahren, bei dem ein flüssiges Polymer über einen Druckkopf mit mehreren Düsen schichtweise aufgebracht und mittels UV-Licht ausgehärtet wird.

Eigenschaften

- Generative manufacturing process

- Manufacture of smooth, precise components and prototypes

- Manufacture of complex components

- Accuracy up to 0.014 mm

- Variety of colors can be shown

- Construction volume: 330 mm (x) 330 mm (y) 200 mm (z)

- Layer thickness: 0.016 mm

- X-axis resolution: 600 dpi

- Y-axis resolution: 600 dpi

- Z-axis resolution: 1600 dpi

Material

RGD720

– Production of transparent prototypes

– IZOD impact strength: 20-30 J / m

– Dimensional stability temperature: 45-50 ° C

– Flexural strength: 80-110 MPa

– Tensile strength: 50-65 MPa

VeroWhitePlus

– Function models with high accuracy

– Production of complex structures with smooth high-gloss surfaces possible

– Very high level of detail and dimensional accuracy

– Visually very close to injection molded parts

– Suitable for prototypes of medical technology products

– Suitable for the production of molded parts

– Color white

VeroBlackPlus

– Function models with high accuracy

– Production of complex structures with smooth high-gloss surfaces possible

– Very high level of detail and dimensional accuracy

– Visually very close to injection molded parts

– Suitable for prototypes of medical technology products

– Suitable for the production of molded parts

– Color: Black

VeroClear

– solid and transparent material

– Used to simulate acrylic glass

– Can also be used as an alternative to glass

– IZOD impact strength: 20-30 J / m

– Dimensional stability temperature: 45-50 ° C

– Flexural strength: 75-110 MPa

– Tensile strength: 50-65 MPa

Applications

VORENTWICKLUNG

→

SERIENTRANSFER

→

MASSENPRODUKTION